Cambridge America, LLC • 63-7 North Branford Rd • Branford, CT 06405 • 203-483-9214

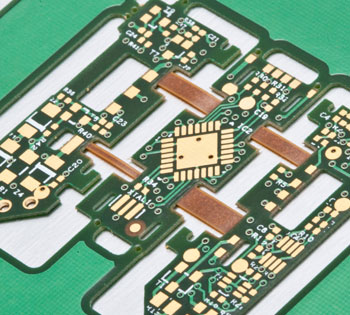

Printed Circuit Board Technology Study – How Fabricators will be affected?

Aug 8th, 2019

The ongoing production of IPC’s 2018 PCB Technology Trends concentrate featured a few noteworthy patterns that will affect the board fabricator going ahead throughout the following five years.

Probably the most noteworthy innovation patterns seen are in the materials fragment. As a whole, it’s perceive that cover materials are the substrates on which circuit sheets are manufactured. Be that as it may, these materials perform basic various capacities. Significant qualities, for example, signal respectability, impedance, recurrence, capacity to withstand high welding and working temperatures are only a couple.

The 2018 overview results demonstrated the requirement for speed and low misfortune as basic elements of the materials picked. This is the advanced age, and with the Internet of Things, virtual and enlarged reality, vehicle-to-vehicle correspondence, and so forth. The requirement for low-misfortune and ultra-low-misfortune materials keeps on developing as a level of circuit sheets created. The OEMs’ reactions recommended that applications for frequencies more prominent than 20 GHz will practically twofold by 2023. In fact, there is a little gathering of OEMs pushing 77 GHz presently. There is discourse that throughout the following 5-8 years we will see 100 GHz. The review results additionally demonstrated a noteworthy uptick in the utilization and determination of liquid crystal polymer (LCP), PTFE and artistic dispatched materials so as to help the requirement for higher working frequencies.

These materials must give upgraded electrical properties, however should likewise give higher unwavering quality against warm decay, working temperature boundaries and all the more working cycles every day. These issues place noteworthy weight on the material execution. Temperature of disintegration (Td) has expecting more significance going into 2023. As major OEMs keep on pushing without lead get together and require enhancements in long haul unwavering quality, warm deterioration of materials become a noteworthy impact. There is a developing requirement for Td more noteworthy than 340 C.

These patterns are huge and will require an adjustment in the manner PCB fabricators approach procedures used to create these circuit sheets. Changes will be required in interlayer handling, overlay hardware and parameters, surface readiness and metallization. These higher presentation materials become increasingly hard to process synthetically. Accordingly, working windows and the requirement for improved procedure controls ends up fundamental moving into 2023 and past.